Comprehensive Guide to Building an Efficient Sesame Oil Production Line: Equipment Selection and Capacity Matching

This article provides an in-depth guide to establishing a high-efficiency sesame oil production line from scratch, focusing on equipment selection, capacity matching, and energy-saving optimization techniques. It covers the roles and key parameters of essential machinery such as washers, dryers, screw oil presses, filters, and automatic filling lines. The article explains how to modularly configure equipment based on daily output demands ranging from 50 to 200 kg. Advanced energy-saving technologies including heat recovery, variable frequency motor control, and automation systems are analyzed alongside typical energy consumption data to aid rational investment decisions. A practical case study of a small-scale plant layout demonstrates scientific equipment matching and capacity planning, supported by planning tools and decision matrices. Written with clarity for non-specialist investors, the article concludes with a subtle introduction to the technical advantages and comprehensive after-sales support of the Qingque Group’s high-purity sesame oil extraction systems, encouraging further inquiries.

Complete Guide to Building an Efficient Sesame Oil Production Line: Equipment Selection & Capacity Matching

Establishing a high-performance sesame oil production line requires a strategic approach to equipment selection and capacity planning. Whether you are launching a startup or expanding a small-scale processing facility, understanding the synergy between various machines and how to optimize energy consumption can significantly impact operational efficiency and profitability.

Key Equipment and Their Functional Roles

The backbone of a sesame oil production line includes the cleaning machine, drying machine, screw oil press, filtering system, and automated filling line. Each plays a crucial part in ensuring oil quality and throughput:

- Cleaning Machine: Removes impurities such as stones, dust, and foreign particles for optimal raw seed quality.

- Drying Machine: Reduces moisture content to ideal levels (4-6%), preventing oil degradation.

- Screw Oil Press: Core extraction unit with capacity typically ranging from 50kg to 200kg seeds per day, adjustable to meet different scales.

- Filtering System: Ensures oil clarity by removing residual solid particles and impurities.

- Automated Filling Line: Enhances packaging speed and hygiene for finished oil products.

Modular Capacity Matching for Targeted Production

Production capacity planning should be aligned with your daily output goals. For instance:

- Small-scale factories (50-80 kg seeds/day): Utilize compact cleaning units, single-screw oil presses with 1-2 ton/day throughput, and manual or semi-automatic filling lines.

- Medium-scale facilities (100-150 kg seeds/day): Incorporate multi-stage cleaning, drying machines with adjustable thermal zones, and automated screw presses integrated with PLC controls.

- Large-scale operations (200 kg seeds/day and above): Demand multiple parallel screw presses, industrial drying tunnels with heat recovery, fully automated filtering, and rapid bottling lines.

This modular configuration approach maximizes resource usage, controls upfront capital expenditure, and enables scalable growth.

Energy-Saving Technologies and Performance Metrics

Energy efficiency is a critical consideration in modern sesame oil production. Implementation of advanced technologies can reduce operational costs significantly:

- Heat Recovery Systems: Capture and reutilize exhaust heat from drying machines, reducing fuel consumption by up to 25%.

- Variable Frequency Drive (VFD) Motors: Adapt motor speed to load demands, bringing energy savings in intermittent processes.

- Automated Control Systems: Monitor and adjust parameters such as temperature and pressure in real-time, optimizing production and minimizing waste.

For context, a standard drying machine without heat recovery may consume 1000 kWh per 100 kg of sesame seeds processed, while integrating heat recovery reduces this to approximately 750 kWh—a 25% energy reduction.

Case Study: Optimizing a Small Factory Setup

Consider a newly established sesame oil processing plant targeting 100 kg/day. Through modular equipment selection and energy optimization, the plant achieved:

- Selection of a 100kg/day screw oil press combined with a batch drying machine featuring heat recovery.

- Integration of automated filtering and semi-automatic filling lines, reducing labor requirements by 40%.

- Estimated energy reduction of 20% compared to traditional setups, cutting annual power consumption by approximately 12,000 kWh.

This design was supported by a customized planning tool incorporating seed input, throughput, and energy parameters, enabling precise cost-benefit analysis.

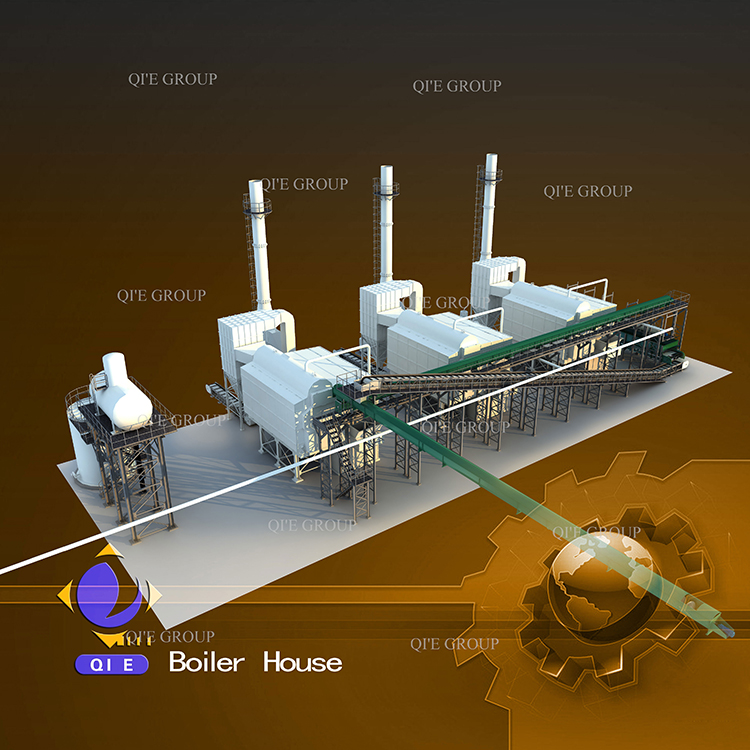

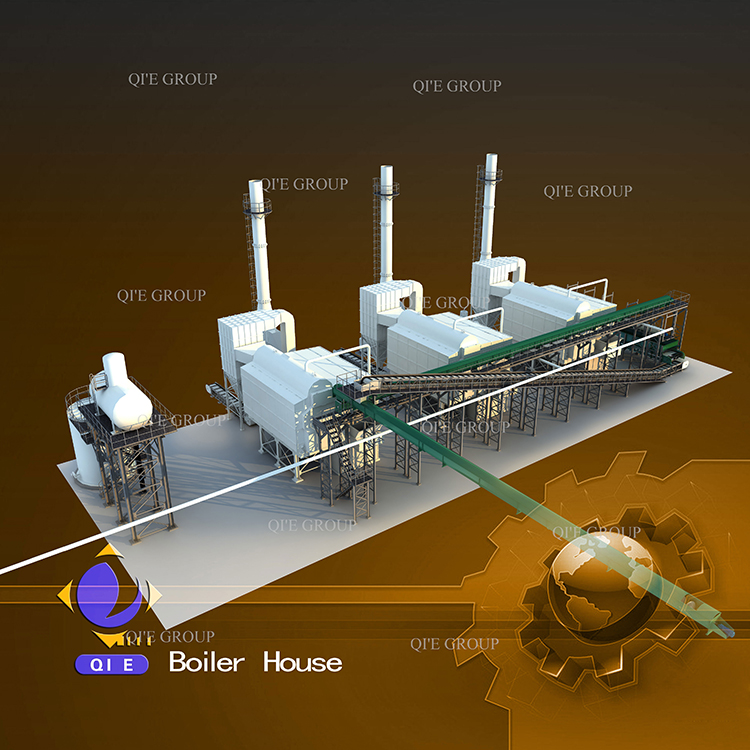

Expert Solutions from Qeek Group for Premium Sesame Oil Extraction

Qeek Group provides state-of-the-art sesame oil extraction systems engineered for high purity and efficiency. Their turnkey solutions offer:

- Fully integrated equipment packages tailored to your production scale.

- Advanced automation for consistent oil quality and reduced labor cost.

- Proven energy-efficient technologies delivering sustainable operations.

- Comprehensive after-sales service ensuring long-term operational reliability.

Businesses aiming for optimized sesame oil production and sustainable growth can rely on Qeek Group’s expertise to enhance their manufacturing capabilities.